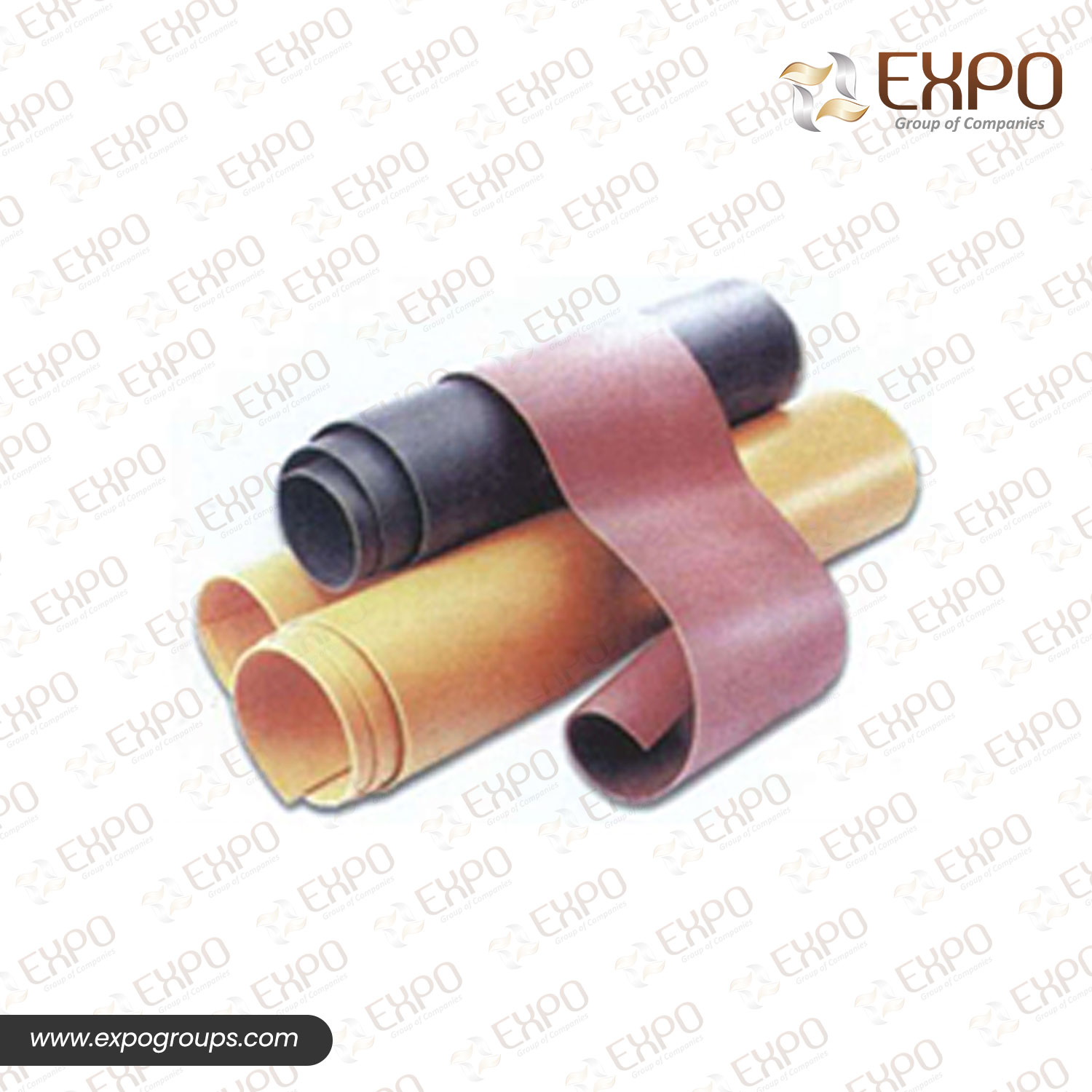

Turcite Sheet

What is a Slideway?

Slideway is a proprietary formulation of PTFE material impregnated with bronze and friction reducing additives.

What does a Slideway do?

- Reduces friction and wear

- Reduces damage caused by mechanical problems

- Increases accuracy

- Extends machine life

- Saves energy

How does a Slideway linear bearing system work?

By providing self-lubricating, low coefficient of friction linear bearing surface between two metal interfaces, is normally attached to the moving surface bya bonding method.

The Slideway bearing moves with the work table or tool holder along the steel or cast iron mating of the tool way. The static and dynamic friction of is nearly the same on both cast and hardened or soft steel ways.

Applications

Planers, milling machines, SPMs, sharpers, horizontal & vertical boring machines, hydraulic & pneumatic power presses, press brakes, all types of grinders, radial drills, automatic screw machines, gear hobbers, gear shapers, multi-spindle automats, broaching machines, CNC machines and machining centres.

the solution you have been looking for to reduce the effects of friction on your machine tool accuracy. It is applicable both for new designs and while rebuilding guideways.

The results conform to the machine tool manufactures’ re-builders’ specifications.

Advantages

The advantages of Poly Fluoro Slideway tape bearings in comparison with traditional solutions are: Coefficient of Friction: Slideway has the lowest coefficient of friction as compared to other guiding materials. It is self-lubricating with an unlimited shelf life Wear: Slideway has outstanding wear resistance and is recommended for mating with surfaces having a Hardness (BHN) of 180-220 with a Roughness (mm) of Ra<0.6 Contact Pressure: At contact pressures up to 11 N/mm2 it is comparable to other guiding materials and additionally has excellent vibration and damping properties

Stability of Dimensions: Slideway will not swell or shrink. Its inert property assures stability of dimensions

Mounting: Slideway is secured to the metallic guide elements by bonding The etched side of the tape is easily bondable with a conventional 2-pack industrial adhesive